The main ways to improve the efficiency of hydro-mechanized complexes are: reducing material consumption and energy consumption, increasing abrasive and corrosion resistance, reducing operating costs.

The use of rubber floating slurry pipelines as part of diesel or electric dredgers can solve most of these problems.

Floating slurry pipelines are used for transportation of abrasive sand-gravel combinations, sand of various categories, highly abrasive materials.

The design and manufacturing technology of floating slurry pipelines are patented.

Floating slurry pipelines are produced according by TU 2550-010-23770232-2013.

Slurry pipeline design

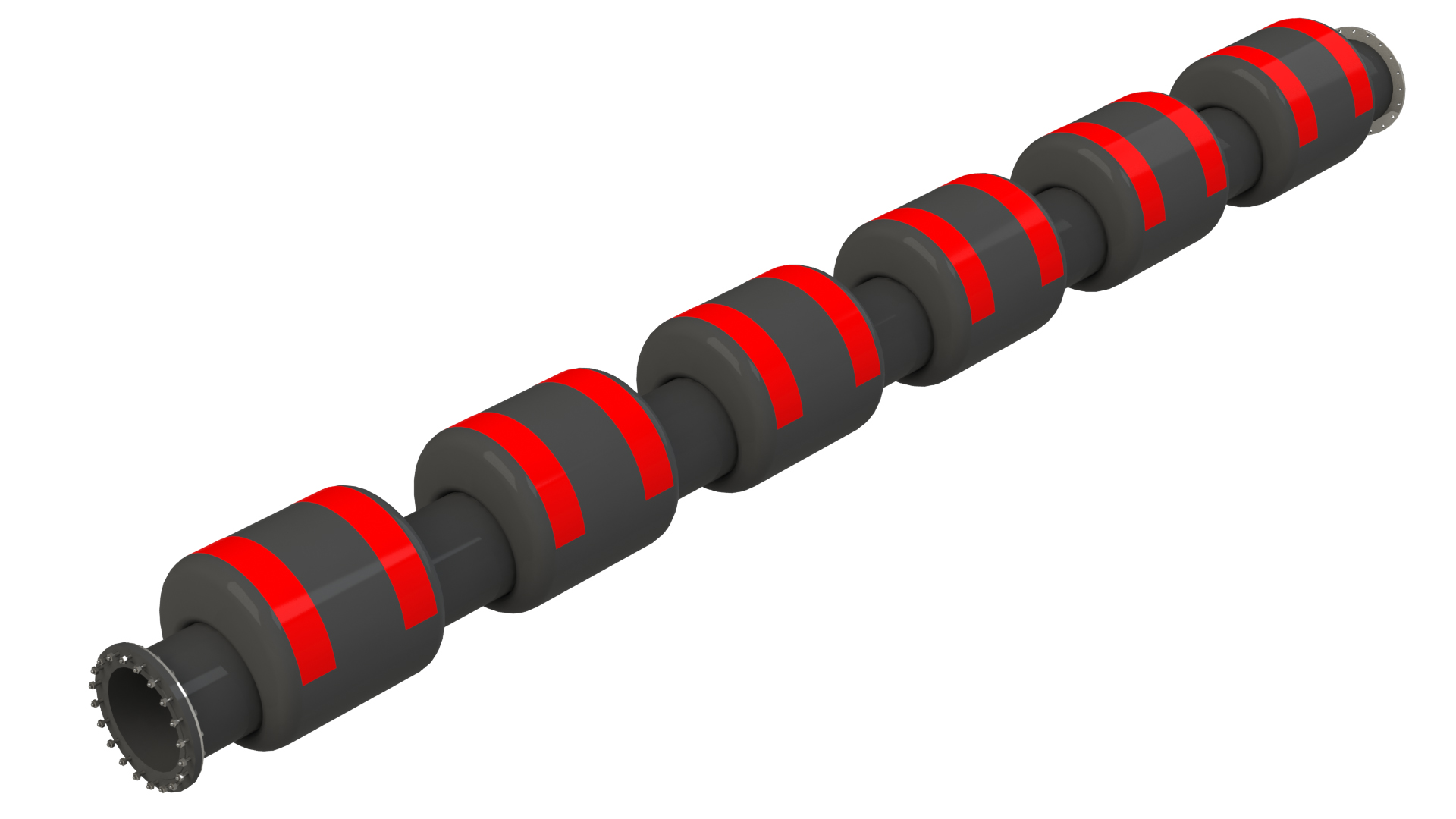

Floating slurry pipeline is a rubber-fabric pipeline with fixed floats. Floats are made of composite material resistant to mechanical, chemical and natural influences and filled with foam material. On the top of the floats there are special fasteners for laying the power cable.

The number of floats is determined by agreement with the customer, and the required buoyancy of the slurry pipeline is calculated, depending on the concentration of the pumped environment. The flanges of the slurry pipeline are made of standard design or rotary. In the design of slurry pipeline flanges it is possible to mount the signal resistant to the sections of gruntorad.

The use of elastic pipelines avoids the use of ball connections. The absence of ball connections, the elasticity of the slurry pipelines allow to move hydraulic mixtures of high concentration-up to 50% of the solid fraction.

Floating slurry pipeline is manufactured in sections. The length of the section is up to 10 meters.

Extraction of sand, gravel-sand mixtures, etc. Hydraulic transport of abrasive combinations to ash dumps. Dredging works. Pan out of dikes and dams through dredging.

Delivery of production is carried out to any point of Russia, the near and far abroad, the following transport companies: "zheldorekspeditsiya", "Autotrading", "Sherl TK", "RATEK", "Energy", "Business Lines".

Shipment of production is made after receipt of an advance payment in the following terms:

road transport — 3 workday;

road transport — 3 workday; air transport — 3 workday;

air transport — 3 workday; railway baggage — 3 workday;

railway baggage — 3 workday; railway container — 7 workday;

railway container — 7 workday;If customs clearance is necessary, the shipment period is increased by 2-3 working days.