Developed joints are designed for torque transfer between units, an engine and a pump or between an engine and a generator. The joints have high compensating and damping properties, allow to reduce the vibration level of in-stallations, to raise their durability, to simplify and reduce the cost of providing service.

Highly elastic joints allow to simplify considerably installation, for example, pump installations since they compensate assembly and working radial displacements of shafts being connected, of a value up to 1,5 mm, and axial displacements – of a value up to 3 mm. Joints have no rubbing parts, so they have a high durability and practically do not require any maintenance for 5 years.

In the joints design, elastic elements made of special sorts of rubber having high elasticity and cyclic durability are used. For obtaining of demanded by the customer torsional rigidity of the joint sorts of rubber possessing various elasticity are used.

Modern technology of coupling of rubber with metal has allowed to reach such durability of coupling of rubber with metal that surpasses durability of the rubber itself. In the process of joints’ manufacture the index of strength of rubber with metal coupling is constantly supervised.

Design and technology of joints are patented.

Joints are made according by TU 4171-003-23770232-2004.

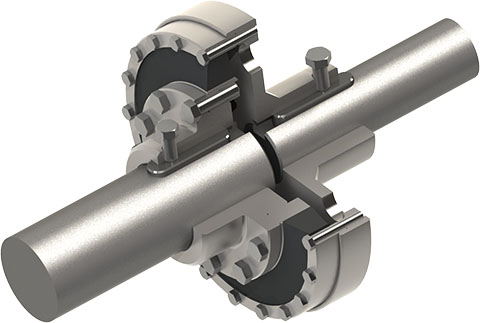

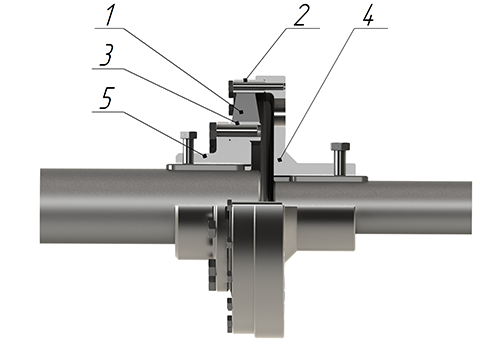

1 — rubber elastic element;

2, 3 — metal rings, vulcanized to the elastic element;

4, 5 — half-joints.

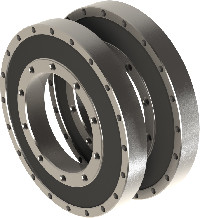

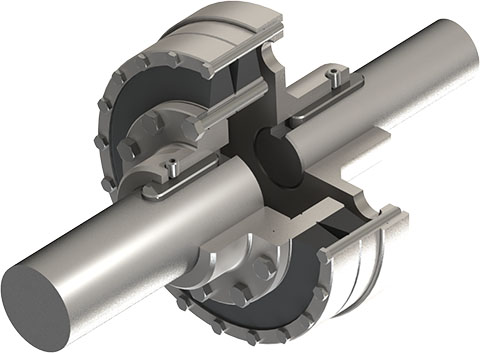

Highly elastic joint VMD-2

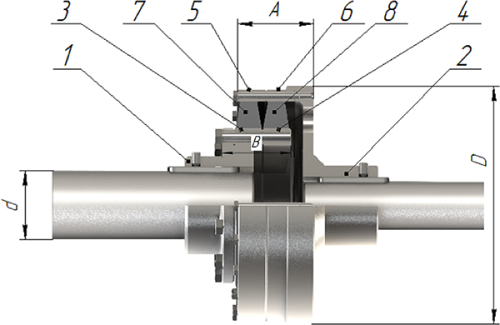

1, 2 - half-joints; 3, 4 - internal rings; 5, 6 - external rings; 7, 8 - rubber elastic elements vulcanized to the rings 3, 5 and 4, 6 accordingly.

Energy, industry. They are installed to reduce vibration in the transmission of rotation between units with high speeds and high torque.

Delivery of production is carried out to any point of Russia, the near and far abroad, the following transport companies: "zheldorekspeditsiya", "Autotrading", "Sherl TK", "RATEK", "Energy", "Business Lines".

Shipment of production is made after receipt of an advance payment in the following terms:

road transport — 3 workday;

road transport — 3 workday; air transport — 3 workday;

air transport — 3 workday; railway baggage — 3 workday;

railway baggage — 3 workday; railway container — 7 workday;

railway container — 7 workday;If customs clearance is necessary, the shipment period is increased by 2-3 working days.